Troubleshooting

If you think your vehicle might have a turbo-related problem, stop before you replace because turbo damage can often be a symptom of an underlying problem rather than the cause itself.

A lack of power, noisy performance or excessive smoke or oil consumption could result from a faulty fuel injection system, restricted or blocked air filters, a damaged exhaust system or a lubrication problem.

So, before you replace your turbo, check for a complete diagnostic list – and then if there is no obvious cause, make sure your turbo specialist completes an extensive troubleshooting program.

Check List if You Experience:

Lack of Power

- Check that filter, hoses and pipes are clean and in good condition

- Check that the fuel injection system is in good condition and correctly adjusted

- Check that the exhaust system, including catalyst and DPF, is not blocked or damaged

Noisy Performance

- Check that the pipework and support brackets are not loose or damaged and that the connections are good

- Check for any leakages or cracks in the intercooler

Excessive Smoke or Oil Consumption

- Check that air filters are not restricted or blocked

- Check that engine oil specifications strictly correspond to car manufacturer's recommendations

- Check that the oil drain pipe is clean and not restricted

- Check for excessive pressure in engine crankcase and correct function of engine breather system

- Check that hoses and joints are in good condition

- Check for lubrication problems in engine block if oil or carbon deposits are found on exhaust manifolds or in the turbine

The causes for turbo damages usually fall into the following four categories:

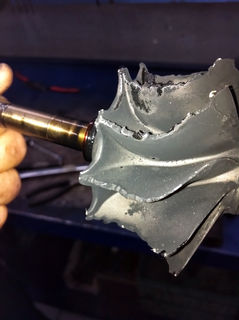

Foreign Objects

Turbo wheel damage, caused by small objects entering the turbine or compressor housing at high speed, leading to imbalance.

Lack of lubrification

Turbo fatigue cracking and material transfer created by metal friction and high temperatures as a result of oil inlet supply restrictions, incorrect gasket placement and use of liquid gaskets or poor quality lubricants.

Oil contamination

Turbo bearing system damage caused by a high concentration of carbon suspended in oil, created by extended oil change intervals or poor maintenance. Bearing damage caused by a steel shot suspended in oil following a major engine overhaul.

Overspeed and excessive temperature

Turbo damage caused by working beyond its designed parameters or outside the vehicle manufacturer’s specification. Maintenance problems, engine malfuction or unauthorized performance upgrades can push turbo rotating speeds beyond its operating limits, causing fatigue failure of compressor and turbine wheels.